The following is an excerpt of an article published in MechSE News Spotlight, dated 16th April 2009.

MechSE researchers have created a self-powered microfuel cell that’s so small it can be integrated into a microchip. It can make its own fuel on-demand and is several times more powerful than a battery.

Novel Fuel Cell Creates Big Power on a Small Scale

In 2007, scientists at Harvard University demonstrated a winged robot that was no bigger than a housefly. The microbiotic fly’s 15 millimeter long carbon fiber wings flapped and twisted just like an insects wings, but the micro-aerial vehicle remained tethered to an external power source.

One of the biggest challenges to developing self-controlled micro- and nano devices is the lack of an equally small power source. Batteries can be miniaturized, but they don’t produce enough power for their weight. Hydrogen fuel cells can be scaled down, but hydrogen gas is difficult to contain and therefore difficult to store and transport. The goal now is to develop a self-powered device that is so small it can be integrated into a micro or nano-device. Such a self-powered device could enable a nanorobot to sense and adapt to its environment, manipulate objects, take actions and perform complex functions without adding much bulk or weight. It could power medical implants, wireless sensors, and enable mobile devices to monitor the weather or conduct surveillance.

Toward that end, MechSE doctoral student Vikhram Swaminathan and postdoctoral researcher Likun Zhu, along with Professor Mark Shannon, have created a self-powered microfuel cell that is small enough to be integrated into a microchip. Like the fuel cells in some cars, the MechSE researchers’ microfuel cell contains a metal hydride that produces hydrogen when mixed with water. But, unlike the fuel cell in a car, which requires additional power to pump water into the metal hydride, the microfuel cell makes use of a key principle of microfluidics: Surface effects, such as surface tension, dominate at very small scales. “If you want to maximize surface effects, area to volume scaling gives you an advantage factor of 10,” Swaminathan said.

By exploiting that principle, he and Zhu have developed a smart way to control their device without an external source of power or having to parasitically produce power. They equip it with a microchannel that’s 100 microns thick and 5 microns deep. When water comes into contact with the microchannel walls, it is instantly pumped through the channel via surface tension. “You don’t need to use power to pump water through the channel,” Swaminathan said. “Surface tension does it for you.”

Better yet, he and Zhu have added a 2-micron thick and 5-micron deep polyimide valve that provides autonomous control of the water flow via an ingenious feedback system. “When the demand for fuel is high, the hydrogen pressure is low and the valve is open,” Zhu explained. “When the demand is low, hydrogen builds up. The resulting hydrogen pressure closes the valve and keeps the water from being delivered to the channel.”

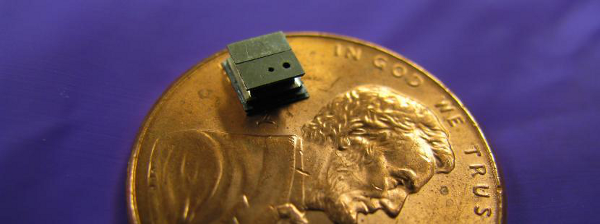

The entire device is only about 10 microliters—small enough to be integrated into a microchip—yet it generates more power than a battery. At about 150 watt hours per liter, the energy density compares well with state-of-the-art micro-batteries; while at peak power the MechSE researchers’ fuel cell sustains 360 watts per liter for several seconds—at least an order of magnitude higher.

While the device works really well, there’s still room for improvement. “We still need to characterize it across a range of performance,” Swaminathan said. Meanwhile the two researchers are also working with Professor Richard Masel, a professor in the Department of Chemical and Biomolecular Engineering, to make their device even smaller. “That has been our biggest challenge so far,” Zhu said.