Research Highlights

Click on any panel to expand or hide details

High AR & Atomic Layer Etch for Memory & Logic Applications

I have extensive R&D experience in semiconductor etch: including front-end high aspect-ratio or selective atomic layer etch, as well as back-end dual damascene and packaging trench/via etch. My contributions include process and hardware pathfinding to accommodate the shrinking lateral size, high density and vertical scaling of structures, including 300mm wafer-scale yield enhancements at HVM customer fabs. Among critical apps, viz. 3D NAND Contact/Capacitor Cell/DRAM Gate-Bit Contact etch, I have patented fundamentally new plasma etch regimes that overcome aspect-ratio limitations and trade-offs at tight pitch to deliver extremely vertical profiles needed for enterprise class performance. Among semi-critical Slit/Deep Chop and back-end single/dual damascene low-K dielectric etch modules, I have established processes with balance of excellent profile control and throughput for cost-effective performance.

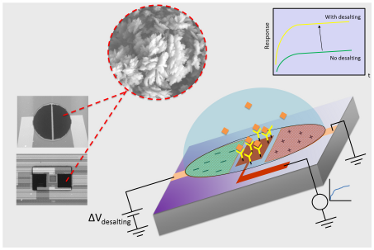

Label-free Cancer Detection with FET NanoBioSensors

My doctoral thesis research was on studies of electrostatic control of ionic environments. Salt ions are necessary for biomolecule stability and function, but cause extensive shielding of biosensors. I implemented a novel method to improve the sensitivity of a FET nanobiosensor through localized desalting. The end goal is direct electrical sensing of analytes from high salt buffers that are isotonic with physiological fluids (viz. blood, serum etc.). Closely associated with this work is a deeper fundamental undertstanding of electrical double layers. Label-free detection with such a nanobiosensor is particularly beneficial for application at the point-of-care, such as cancer treatment.

Microfluidic Separation of Colloidal Nanoparticles

Dielectrophoresis scales very weakly in the sub-micron regime. I demonstrated a microfluidic technique that leveraged enhancements through combined AC/DC electrostatics to improve separation forces. This methodology can be extremely beneficial in separation systems and water treatment as upstream elimination of colloidal foulants will improve the efficiency of reverse osmosis desalinators. The size scale is also relevant for capture, patterning and manipulation of viruses and other macromolecules in biomicrofluidic systems.

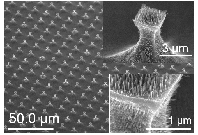

3-D Out-of-Plane Nanofabrication of Silicon

A side project during my doctoral research led to one of my finest demonstrations of micro/nanofabrication across multiple scales. In this work, I nanofabricated structures in single crystal silicon, using photolithography-free patterning and metal assisted chemical etching (MACEtch). I developed a technique for lateral etching of nanopillars into sidewalls of patterned substrates. This approach facilitates patterning multiscale hybrid structures in a rapid and highly scalable single mask process flow. Applications include microfluidic devices for rare cell capture, energy storage and nature-inspired hierarchical-reentrant structures for superhydrophobic surfaces (>170⁰ contact angle) with ultra-low hysteresis (<1⁰ sliding angle).

A side project during my doctoral research led to one of my finest demonstrations of micro/nanofabrication across multiple scales. In this work, I nanofabricated structures in single crystal silicon, using photolithography-free patterning and metal assisted chemical etching (MACEtch). I developed a technique for lateral etching of nanopillars into sidewalls of patterned substrates. This approach facilitates patterning multiscale hybrid structures in a rapid and highly scalable single mask process flow. Applications include microfluidic devices for rare cell capture, energy storage and nature-inspired hierarchical-reentrant structures for superhydrophobic surfaces (>170⁰ contact angle) with ultra-low hysteresis (<1⁰ sliding angle).

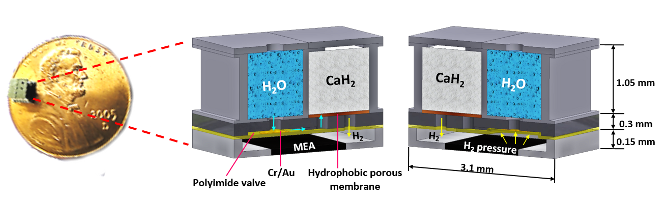

Micro Fuel Cell PowerMEMS

During my master’s, I demonstrated one of the world's smallest micro fuel cell PowerMEMS, that performed with the highest combination of energy and power density. The research was focused on miniaturizing hydrogen sources, and integrating them with fuel cells into single power generators for MEMS and ultraportable devices. This is an area of tremendous opportunity, for developments in scaling down power sources have struggled to keep pace with MEMS/NEMS; the demand for packing more energy into smaller volumes has only been reasonably met in portable and mesoscale technology. Metal hydrides have been widely tipped as candidate fuels to enable the hydrogen economy, albeit fundamental issues that need to be addressed to integrate them with fuel cells. Using these metal hydrides as the source, I studied the effects of mass transport on hydrogen generation and fuel cell performance. During the intergration, I implemented a passive microfluidic control valve and surface tension pump for water transport to the hydrolysis reaction, resulting in a simple demand regulated hydrogen production and power supply.

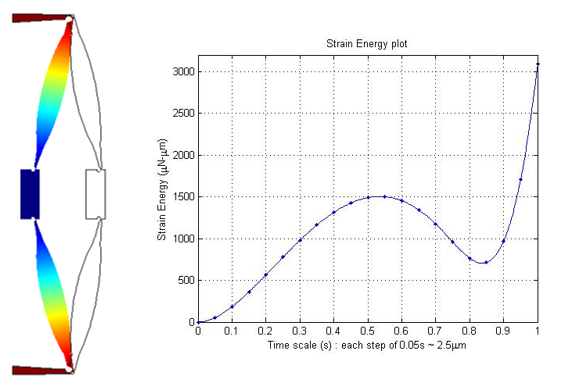

Simulation and Synthesis of Compliant MEMS

I got my first experience in MEMS through the JNCASR Summer Research Fellowship Award, during which I worked with Prof. G. K. Ananthasuresh at IISc on modeling of electro-thermal-compliant microactuators. I performed simulations on compliant mechanisms and electro-thermal actuation to synthesize and develop energy-efficient high force bistable switches. These devices are analogous to four-bar mechanisms, the links and joints here replaced by a single suspended polysilicon structure with distributed compliance.